Double Pieces Folder Gluer (CL2400)

CL double sides semi-auto folding gluer machine This machine make an improvement that based on double sides synchronous ;

Basic Info

| Model NO. | CL2400 |

| Type | Simple Gluer |

| Automatic Grade | Semi-Automatic Folder Gluer |

| Driven Type | Electric |

| Packaging | Cartons |

| Machine Model | Cl 2400 |

| Min Sheet Size | 300*300mm |

| Max. Sheet Size | 2400*1000mm |

| Max. Speed | 50m/Min |

| Total Power | 0.75kw |

| Dimension | 2300*2720mm |

| Power Supply | 380V 50 Hz |

| Transport Package | Plastic Film |

| Trademark | Jiasun |

| Origin | China |

| Production Capacity | 5 Sets/Month |

Product Description

CL double sides semi-auto folding gluer machineThis machine make an improvement that based on double sides synchronous folder gluer, it achieves two sides operating independently or synchronously.

| Model | Min.box size | Max.box size | Max. Speed | Total power | Dimension | Power supply |

| CL-2400 | 300x300mm | 1000x2400 mm | 50 m/min | 0.75kw | 2300×2720mm | 380v |

I. Features of the machine:

The machine is suitable for board and box folding and gluing. Achieving the combination of automation with manual. It includes feeding , film grinding, folding and gluing. bottom and side gluing of the box .Easy operation and high efficiency . About this kind mode, is mainly used for two pieces sheet feeding, for color and printed boxes.

II. Machine Structure:

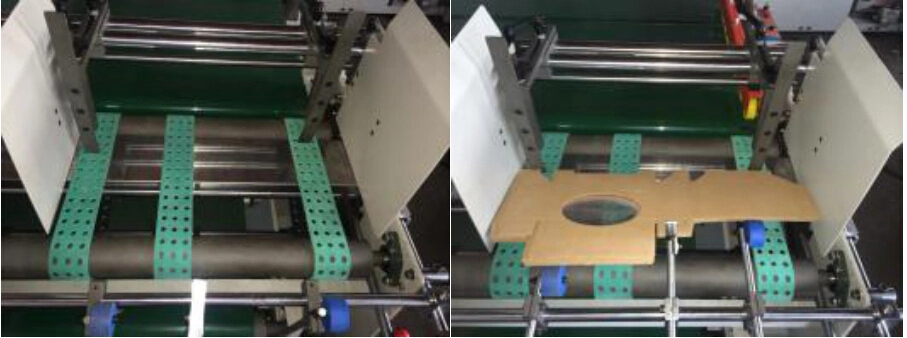

A) Feeding part

The belts adopt the rubber material with holes which make conveying stably .Feeding shaft is made of thick wall steel pipe ensuring the concentricity. The surface of the shaft is specially phosphated for anti-rust. The method of feeding adopts belt conveyor with help of both sides lays and back lay.

B) Conveying part

The conveyor part adopts PVC green belt cooperate with pressing roller and photoelectric sensor .Machine stops when the sensor detects there is a sheets, after operator move off the sheet the machine will restart .

C) Gluing part

The gluing box adopts the stainless steel with adjustable glue volume function. Gluing roller can be customized ,it has 8mm ,12mm and 20mm. There is no need for gluing maintenance. Operator can use the wet towel to cover it and reduce oxidation .If long time no used , please draw off the glue and add water then cover with wet towel

D) Pressing part

The pressing parts is adopts up and down belts structure. Using thick steel pipe support, the speed of pressing can be adjusted through the electrical button .

E)Grinding part

The machine can grind UV coating box and film box.

Method :the speed can reach 2800 circle per minutes ,when the box go through the machine it can grind the surface of the box .

F) Electric part

Frequency :taiwan Delta relay :Omron

Other electric :well known brand

You may also like

Send inquiry

Send now