Huize Metal Stamping Auto Metal Purchase Mental Bending Sheet Mechanical Transmission Part Automobile Hot Foil Machine Stamping Parts

Overview HUIZE METAL STAMPING Auto Metal Purchase Mental Bending Sheet Mechanical Transmission Part Automobile Hot Foil ;

Basic Info

| Model NO. | Metal Stamping |

| Type | Cold Stamping |

| Processing Type | Deep Drawing |

| Material | Aluminum |

| Mould | Multistep Progressive Dies |

| Surface Processing | Electroplating |

| Fine Blanking | Multi-Position |

| Process | Forming Process |

| Industry | Auto Accessories |

| Tolerances | 0.1mm |

| Customized | Customized |

| Product Name | Metal Stamping |

| Keywords | Precision Metal Stamping |

| Surface Finish | Zinc, Chrome Plated, Electrophoresis, Powder Coat |

| Drawing Format | 3D/CAD/Dwg//Step/Pdf |

| Metal Stamping Tolerances | 0.02mm |

| Sizes | Customized |

| Color | Customized |

| Metal Material | Steel Stainless Steel, Brass, Aluminum, etc |

| More Processing | Machining, Laser Cutting, CNC Bending, Welding |

| Surface Treatment | Brushing, Polishing, Electrophoresis, Anodized |

| Service | OEM Sheet Metal Fabrication Services |

| QC System | Full Inspection Before Shipment for Processing |

| Lead Time | Depends on Customer′s Drawing and Request |

| Quality Control | Professional Inspection |

| Certificates | ISO9001:2015 |

| Transport Package | Standard Packaging or Customized |

| Specification | Standard specification or customized |

| Trademark | HUIZE METAL STAMPING |

| Origin | Hebei, China |

| Production Capacity | 1000000 Pieces Per Month as Per Drawing or Sample |

Product Description

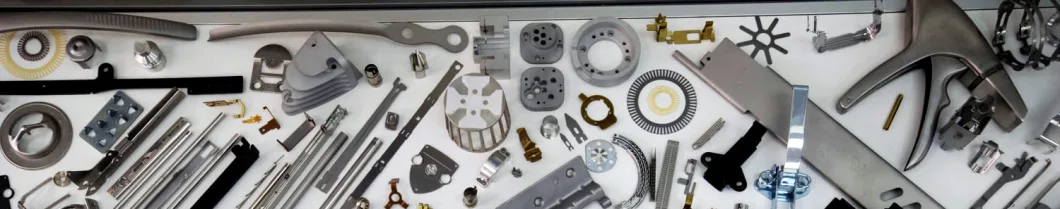

HUIZE METAL STAMPING Auto Metal Purchase Mental Bending Sheet Mechanical Transmission Part Automobile Hot Foil Machine Stamping PartsProduct Description

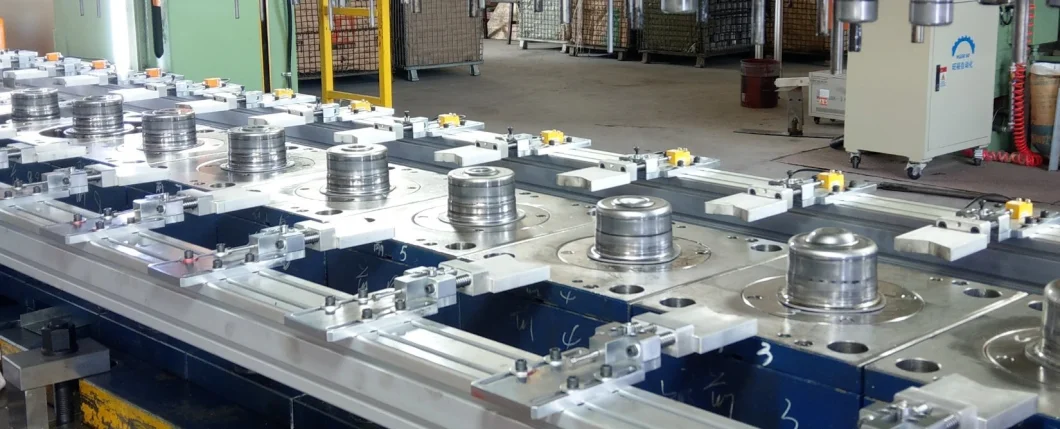

We are a professional custom metal parts manufacturer in metal stamping and deep drawing with over 15 years of experience, equipped with precise Power presses and hydraulic Press to work with a processing accuracy of up to 0.01 mm. We are equipped with manufacturing metal stamping dies and stamping metal parts produced according to the customer's drawing or sample. 2. STAMPING DIE/MOULD DEVELOPMENT

Our company specializes in stamping die and mould design, manufacturing and processing with over 15 years of experience. We can help with your metal stamping die/mould development from ideas to a product and manufacture single-stage die or progressive die according to the customer's order quantity and requirements.3. SHEET METAL FABRICATION

Except for metal stamping, we also offer the most cost-effective way for your project according to the customer's order quantity, we can use laser cutting, CNC punching and CNC bending automatic production, We can cut all kinds of sheet metal accurately with a wide range of thickness up to 30 mm and tube & pipe.4. ASSEMBLE & SURFACE TREATMENT

We are equipped with a welding machine and riveting machine, which can help us assemble different parts according to the customer's drawing and requirements. We provide various surface treatments according to customers' requests, such as Powder Coating. Plating, Electrophoresis, Anodized, Brushing.Polishing and so on.

Q: Is it available to customize 1 piece product?

A: Yes, it is acceptable. Normally we will not need to make tooling if there is no special construction or profile for the productQ: Can I customize the products even if I have a sketch or idea only?

A: It is available. We can help you to design the product according to your sketch or idea and provided drawings

Q: How long is the leading time from development to mass production?

A: Normally the 1st article can be provided after confirming the design and cost. 30-60 days for first mass production

Q: How about your quality control and after-service?

A: We have a control plan for all of our products and do this for every processing. We also accept inspection by a third party be specified. The warranty should be decided by different products and processes

Q: Do you do all processing of products in your factory?

A: Honest to say no. We provide complex sheet metal products and machinery products to our customers. So some processing has to be outsourced by our partners. Some like surface treatment, hardening and tempering, special processing which needs a special machine, and so on. But we keep the main processing in our facility. And it will help us to provide competitive products and services.

You may also like

Send inquiry

Send now