Sunpack Plastic Band Heat Sealing Bundling Packaging Full Automatic Strapping Machine with Product Line

Basic Info

| Model NO. | Q8S-M2 |

| Strapping Mode | Welding Type |

| Packaging Material | Plastic |

| Driven Type | Electric |

| Structure | Strapping Machine with 2 Belt |

| Material Width | 5, 6, 9, 12mm |

| Material Thickness | 0.45-0.8mm |

| Strapping Speed | 40 Straps/M |

| Power Supply | 220V/110V 50Hz/60Hz |

| Cereficate | CE |

| Tension | 20-400n |

| Loading Weight | 2-25kgs |

| Table Height | 780-850mm |

| Control System | PCB |

| Tape Core Diameter | 200 mm |

| Tape Core Width | 190 mm |

| M1& M2 Motor | Servo Motor |

| M3& M4 Motor | German DC Motor |

| Transport Package | Wooden Case |

| Specification | 1055*700*1400mm |

| Trademark | sunpack |

| Origin | China |

| HS Code | 8422400090 |

| Production Capacity | 100sets One Month |

Product Description

SUNPACK Plastic Band Heat Sealing Bundling Packaging Full Automatic Strapping Machine With Product lineProduct Description

Q8S-M2 Built with durable spare parts and reliable electrical components. Germany Dunker Director current motor enables machine to start working as soon as power connected and No pre-heating and standby- time are required which will help save power consumption. Direct driving design guarantees a low maintenance. Reading tension percentage and heater temperature from the control panel. Faults happen statistics are stored for maintenance analysis.

Features:

High speed up to 40 straps/M

Auto Feeding

Direct motor driving,No belts.

Temperature and tension are displayed from screen

Germany Dunker DC 24V motor, Save power and safe.

Loop ejecting and re-feed function

Instant heating system, persistent temperature

Tension mode: Fixed tension and Fixed length

Switchable Manual and Auto operation

With counting function

One button to clear strap jam

Built for 24 hours continuous operation

Quick strap loading operation

No tooling required for maintenance

No maintenance for Gear box

Tension adjustment: Very easy from control panel

Easy strap loading and unloading

Front and rear pedal operation

Machine technical parameter

| Product name | Full automatic high table strapping machine |

| Item no | Q8S-M2 |

| Material | PP strapping tape |

| Material width*thickness | 5,6,9,12MM(width) x 0.35-0.65mm (thickness) |

| roll Inner diameter | Ø200MM |

| arch size | 800*600mm |

| Max strapping size | L no limit*W700 x H550mm |

| Min strapping size | L120*W200*H100mm |

| Loading weight | 80KG |

| table height | 750-850mm(Can be adjusted) |

| power | 1000W,10A |

| Contral system | PCB+LCD Screen |

| Motor | M1& M2 motor: Servo motor M3& M4 motor: German DC motor |

| strapping speed | 40 straps/min |

| Table conveyor | 2 belts conveyor, 33m/min, frequency conversion speed regulation |

| shell material | Carbon steel sprayed (light gray) |

| Tension | 20-400N |

| Welding method | Constant temperature melting |

| Bonding surface | Bottom bonding surface >90% |

| Packing method | Manual or automatic 1-3 channels optional |

| Mechanical appearance size | L1700*W685*H1530mm/280kg |

| Applicable industry recommendation | Paper products, semiconductors, food, pharmaceutical, etc |

| Customizable items | 1. Dunker DC motor or brushless motor2. PLC+touch screen control system3. Frame non-standard size |

Related Products

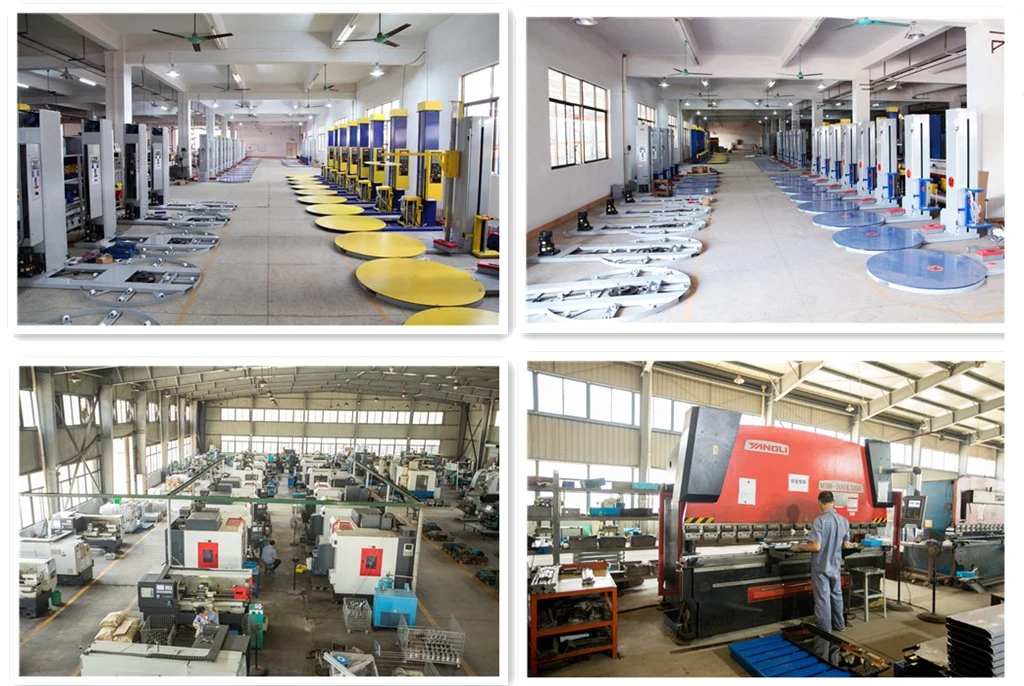

Company Profile

Xutian (Sunpack) was established in 1997 with the goal of providing the best strapping machine in the industry at competitive prices.Xutian (Sunpack)is a group company with 3 branches located in Taizhou, Wenzhou and Dongguan. We dedicate to end of line package development for years. We have more than 30 staff in our RND department . We carry banding machine, strapping machine, pallet wrapper, case sealer and manual strapping tool in our range.Our goal is to make every customer completely satisfied with the best packaging machinery and services through continuous improvement and employee involvement.We believe that innovation is key to our success. Through a firm commitment to research and development, we have earned a reputation for being at the forefront of packaging innovation. We provide our customers with advanced solutions that increase production efficiency, improve load integrity and reduce operating costs. Over the years, we've continuously refined our existing products and created new ones to take advantage of evolving technologies and to meet our customers' ever-changing needs.We appreciate your interest in our company and will be in touch with you as soon as possible to discuss your specific needs.

Shipping & packing

Certifications

Our Service

1.Fast parts delivery

Within 3 days to deliver required parts

2.Fast response

Within 24 hours to give email reply or calling-back and solve the claim

3.24 hours in hall service

Within 24 hours to arrive in cusotmer's location

4.Agent call-in help

Local agents could help for Emergency cases

5.OEM SERVICE

OEM design for all customers