Automatic Window Patching Machine Box Window Patcher (GK-1080T)

Introduction of the machineRolam Window Patching Machine is widely used in the film patching to be package with or witho;

Basic Info

| Model NO. | GK-1080T |

| Automatic Grade | Automatic |

| Gluing Mode | Wheel Gluing Machine |

| Packaging Material | Paper |

| Glue Type | Water Base Cold Glue |

| Application | Paper Box |

| Driven Type | Electric |

| Packaging | Pallets |

| Model | Gk-650t |

| Working Speed | 6000-8000PCS/H |

| Min Paper Size | 200X300mm |

| Max Paper Size | 630X650mm |

| Min Window Size | 80X30mm |

| Max Window Size | 300X260mm |

| Applicable Paper Gram | 200-1000g |

| Film Thickness | 0.05-0.25mm |

| Total Power | 4.4kw |

| Machine Weight | 2800kg |

| Transport Package | Pallets |

| Specification | 4500x1200x1600mm |

| Trademark | RAGAOKE |

| Origin | China |

| HS Code | 8441309000 |

| Production Capacity | 25sets/Month |

Product Description

Introduction of the machineRolam Window Patching Machine is widely used in the film patching to be package with or without the window of the wine box, gift box, Tissue box, cosmetic box etc. It can do paper gluing, film cutting, film pasting and papercollecting.The machine has confirmed the European CE safety standard.

Machine with Tissue box window slitting function.

| Specification of the machine | ||

| Model | GK-650T | GK-1080T |

| Max. Paper Size(mm) | 650*630 | 1080*680 |

| Min. Paper Size(mm) | 100*80 | 140*140 |

| Max. Film Size(mm) | 200*300 | 410*300 |

| Min. Film Size(mm) | 30*50 | 80*60 |

| Film Thickness(mm) | 0.05~0.25 | 0.05-0.25 |

| Max. Working Speed | 10000pcs/h | 10000pcs/hour |

| Cardboard | 200~800g/m2 | 200-800g/m2 |

| Corrugated Paper | ≤7mm | ≤7mm |

| Total Power | 11kw | 9kw |

| Total Weight | 2000kg | 2800KGS |

| Paper feeding with servo motor control | |||

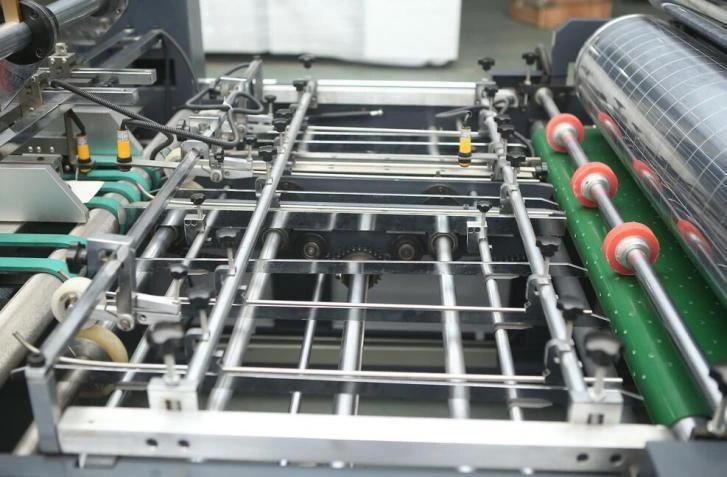

| Paper feeding with servo motor controlThe paper conveying section installed conveying chains with pushing blocks, it can be adjusted according to the paper shape. It is equipped with the 4 photoelectric sensor, detect the paper reaching condition, counting , paper jammed detection.The paper feeder parts is controller by the servo motor, the paper pile make the intermittent movement in the process of the paper feeding,the belts has long lifespan, feedingpapersheets to the conveying sectionstably.Perfect for the cardboard and corrugated window box film pasting. | ||

| Paper conveying sectionThe paper conveying section installed conveying chains with pushing blocks, it can be adjusted according to the paper shape. It is equipped with the 4 photoelectric sensor, detect the paper reaching condition, counting , paper jammed detection. | ||

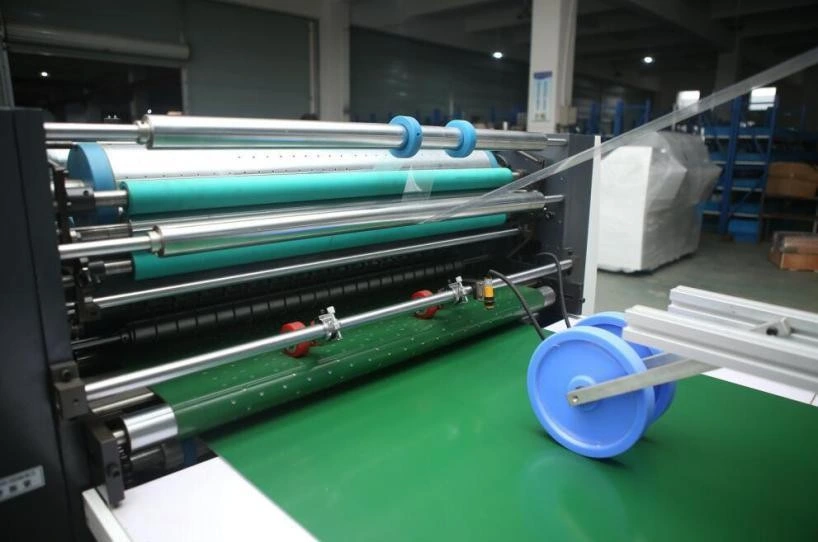

| The gluing parts adopt the adjustable gluing structure , easy to be adjusted according to the paper sheets and the gluing position ,save glue. it is easy for pulling out the gluing parts ,convenient for washing. The gluing roller will stop gluing paper when the machine stop. And the conveying parts down automatically, make sure the machine clean and easy to operate. | ||

| The patching products conveying to the paper delivery plate, finish the paper accumulation and collection Paper delivery parts can be adjustsingle.

|

- PriceTerm: FOB NINGBO

- Payment: T/T (30% for deposit,70% beforedelivery)

- Loadtime: 30 working days at sight thedeposit.

- Packaging: Wooden packing applies to export. LCL or 1x20GP container

- After saleservice:

- Spare parts guarantee for one year in machine arrival. if spare parts broken( except wearing spare parts), will be sent freely, buyer should bear deliverycost

- Send the technician for installation & training. Buyer should bear the cost(Visa, round trip tickets,accommodation, and allowance of technician 80USD perday)

You may also like

Send inquiry

Send now