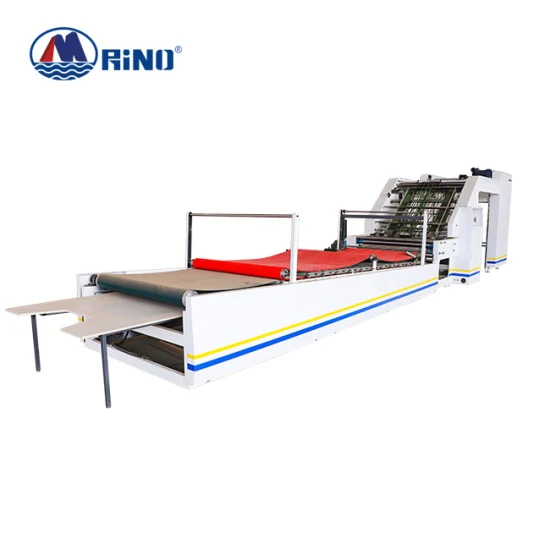

High-Speed Automatic Flute Laminator Machine for Corrugated Board Making

Basic Info

| Model NO. | HF-H1450 |

| Application | Corrugated Board |

| Driven Type | Electric |

| Automatic Grade | Automatic |

| Membrane Material | Paper |

| Plastic Film Mulching Modes | Cold Laminating |

| Performance | Anti Wrinkle |

| Maximum Size(mm) | 1450*1450mm |

| Minimum Size(mm) | 400*450mm |

| Top Feeding Paper Thickness | 200G/M2-500G/M2 |

| Bottom Feeding Paper Thickness | 0.5-13mm |

| Laminate Precision (mm) | 1.5 |

| Max.Speed | 13000PCS/H |

| Overall Dimension | 13500lx2450wx2600h mm |

| Total Weight(T) | 6.5 |

| Total Power | 22kw |

| Transport Package | Plastic Film Wrapped+Wire Fixed in The Container |

| Specification | HF-H1450 |

| Trademark | Rino |

| Origin | China |

| HS Code | 844130 |

| Production Capacity | 10 Sets/Month |

Packaging & Delivery

Package size per unit product 1350.00cm * 245.00cm * 260.00cm Gross weight per unit product 6500.000kgProduct Description

Servo High Speed Flute Laminator For Corrugated Paper Board Carton BoxProduct Description| Product description of flute laminating machine |

1. The most high-end electrical control system, computerized high-speed lamination, up to 13,000 sheets per hour;2. The upper paper feeder adopts high-speed paper feeder to ensure accurate paper feeding under the condition of high-speed paper feeding;3. Bottom paper feeding: The bottom paper conveying structure of the suction belt is driven by a servo motor to make the conveying distance of the bottom paper precise and smooth.4. High-precision coating and conveying with automatic page control of paper and gluing wheel side gluing mechanism, high-speed operation without glue overflow, and adjustable glue return;5. Use multiple sets of photoelectric sensor and the bottom line to advance the relative position, so that the servo motors on both sides of the face paper are driven independently to compensate for the upper and lower paper alignment, which is accurate and smooth;6. The man-machine interface is applied, which is convenient for operation and can automatically detect the operation status, abnormal display and work record, stable performance, CE standard.7. Changing paper specifications can store orders and start automatic adjustment with one button, zero error, and fully intelligent automation.8. The anilox glue roller is equipped with a protective device for anti-sticking glue.9. Intelligent glue supply and recovery system, intelligent cleaning water circulation system.10. Intelligent detection of paper position, intelligent display and alarm system.Product Parameters

| Product parameter of flute laminating machine |

| Model | HF-H1450 | HF-H1650 | HF-H2100 |

| Maximum size(mm) | 1450*1450 | 1650*1650 | 2100×1650 |

| Minimum size(mm) | 400*450 | 400*450 | 400*500 |

| Top feeding paper thickness | 200g/m2-500g/m2 | 200g/m2-500g/m2 | 200g/m2-500g/m2 |

| Bottom feeding paper thickness | 0.5-13mm | 0.5-13mm | 0.5-13mm |

| Laminate precision (mm) | ≤±1.5 | ≤±1.5 | ≤±1.5 |

| Max.Speed | 150m/min | 150m/min | 150m/min |

| Overall dimension | 13500Lx2450Wx2600H | 13900Lx2700Wx2600H | 13900Lx3100Wx2600H |

| Total weight(t) | 6.5 | 8 | 9.5 |

| Total power | 22KW | 23KW | 25KW |

| Product details of flute laminating machine |

This machine adopts German BECKER air pump and a high-speed feeder head paper feeding mechanism. The feeder head is fixed on the linear guide, (other companies are fixed on two iron rods). Input paper size then automatically in place to ensure high-speed feeding. High-speed and accurate delivery of the face paper .

Bottom paper feeding unit

The bottom paper feeding adopts a widened and elongated bottom paper feeding belt, which is stable in paper feeding with Yaskawa servo control system, and the paper is fed with stability and precision with high-power suction fan. Each belt is tightened separately, (others have been changed to overall tightening in order to reduce costs), which greatly reduces the customer's later use cost by tens of thousands. TransmissionThe transmission part adopts timing belt transmission with high precision, low noise and continuous stability. All rollers pass the dynamic balance correction , and the whole machine is stable in operation. The overall adjustment of greatly improves the exchange order speed, change order pressure digital display, more convenient and quick, directly adjust in place.

Our company has nearly 20 years of experience in carton packaging production and professional technical team which can provide reasonable packaging solutions, after-sales service, timely and comprehensive for each customer. Aiming at offering the most suitable solution and professional service, Persisting in client requirement oriented, offering high quality, reasonable price and cordial service which have formed a unique service mode.We sincerely expecting for cooperation with all global clients on the basis of Mutual-Trust, Mutual-Understanding, and Mutual-Benefit.

Workshop

1

Q:What is the machine warranty?

A:one year.

2

Q:Does your machine with CE certificate?

A:Yes, issued by Italian organization

3

Q:What is the production time while placing order?

A:About 30 days

4

Q:What is the delivery time?

A:45-60days after get the payment

5

Q:Can your company handle shipping for customers?

A:Yes, just give us destination sea port or container yard

6

Q:Does the packing strong?

A:Yes, all packages are double-checking before delivery

7

Q:How about after-sales service process?

A: We offer life time A.S.S. Please feel free to contact after-sales department.

8

Q:Do you have machines in stock?

A: for standard model, we have a large quantity in stock. For special model, we need 20-30 days to produce it for you.

9

Q:Do you inspect machines before packing?

A:Of course we do.we have QC department to debug the machine before packing

10

Q:What's the payment term?

A:T/T 30% in advance, the balance paid before delivery.

11.

Q: Do you accept factory visiting?

A:We are highly greeting for your visiting.